Zinc-air accumulator - in search of the better battery

Environmentally friendly battery alternative

Our society needs electricity - available everywhere and at all times. So it's no wonder that batteries have become an integral part of our lives in the age of smartphones, laptops and electric cars. However, current technologies also have disadvantages - such as the use of rare materials that can only be obtained with major environmental impact. Researchers are therefore looking for alternative options and have rediscovered a technology that has been around in its basic form since the 1970s: the zinc-air battery.

Loading and unloading as a challenge

As with lithium-ion batteries, the name already reveals what - in very simple terms - makes up this battery, what it consists of and how it works: the zinc in the cell reacts with oxygen from the air. Because, unlike other types of batteries, there is only one substance that reacts with another (in this case the zinc with the oxygen), zinc-air batteries have a very high energy density - in other words, they deliver more power than a battery of the same size with a different design.

Another advantage of zinc-air batteries is the materials used. Unlike lithium and other rare metals, they are available in sufficient quantities all over the world. As a result, the technology promises not only energy density but also a favorable cost and environmental balance compared to other technologies. However, there are also reasons why zinc-air batteries have so far only been used in niche applications such as hearing aids. Because zinc oxide is formed when zinc reacts with oxygen in the air, zinc-air batteries are difficult to recharge. This is because the zinc oxide would have to be converted back into zinc, which in practice leads to crystalline deposits, which in turn cause short circuits and defects.

Housing from the 3D printer

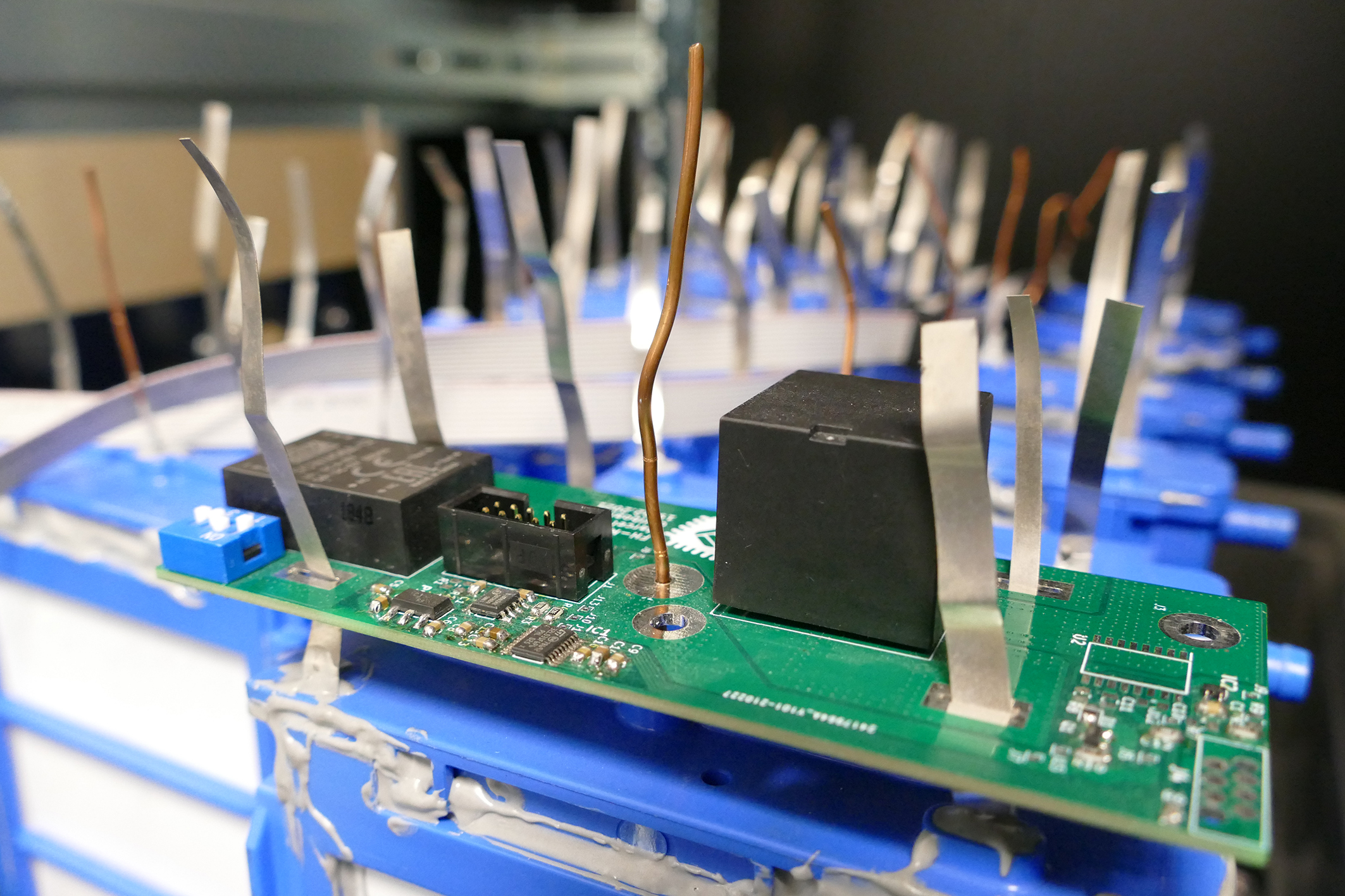

The Münster University of Applied Sciences is one of the institutions conducting research into how the current problems can be solved. Researchers there are working on a new type of zinc-air battery, which they want to charge and discharge with the help of a battery management system they have developed themselves. In order to get closer to a functioning prototype, the project participants in Münster are using 3D printers to create the cell housing, experimenting with different sensors, testing various application scenarios and using impedance spectroscopy to investigate the charging and discharging characteristics as well as the state of charge of the cell. The end result will be a functional demonstrator.

Find out more about the zinc-air accumulator in the 2nd episode of our podcast series. Episode of our podcast series "Future.Make."

At a glance

Total investment: 1,218,335 euros of which:

EU funding: 595,200 euros

NRW state funding: 270,276 euros

Project partners

Project partners: KUNKEL + Partner Ingenieure GmbH, Düsseldorf, EMG Automation GmbH, Wenden, Münster University of Applied Sciences

Runtime

01.05.2016 to 30.06.2020